How to maintain a submersible pump for long-lasting use

- Kong

- 16 ต.ค. 2568

- ยาว 2 นาที

อัปเดตเมื่อ 31 ต.ค. 2568

How to maintain a submersible pump for long-lasting use

Submersible pumps: To ensure a long-lasting pump, in addition to selecting quality products that meet the required standards for the application, another important factor is "maintenance." This article will help you prolong the life of your submersible pump.

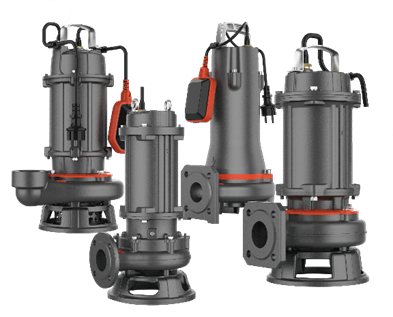

Submersible pumps, or "divo" pumps, are submersible pumps that are submerged in water. Their primary function is to pump water from one source to another. They can be divided into two types based on their use: clean water and wastewater. Specifically, submersible pumps, in order to ensure a long-lasting pump, are not only designed to be high-quality and meet the required standards for the application, but also to ensure "maintenance." This article will help you prolong the life of your submersible pumps. Wastewater treatment products can accumulate dirt and debris, which can negatively impact the pump's internal systems. Failure to maintain these components can also pose a risk. Therefore, it's important to know how to properly maintain your submersible pump.

How to maintain

1. When connecting the pump, ensure proper electrical tape is applied to prevent water from entering the wires. Poor electrical tape can cause water to enter the pump, damaging the pump and potentially harming the user or installer.

2. Be careful of the rubber parts around the wire terminals. When the pump is submerged in water for extended periods, the rubber may deteriorate, allowing water to enter the pump. Therefore, use silicone or sealant to seal the rubber around the wire terminals.

3. Be careful not to let debris or other debris get into the pump. This can cause debris to become trapped in the impeller, slowing down its rotation speed. A fine screen should be installed to prevent debris from entering the pump.

4. Do not connect the wires longer than 10 meters, as a voltage drop will slow the pump's operation and damage the motor.

Submersible pumps for wastewater

1. Check the voltage and current to ensure they meet the specifications on the product nameplate. Do not exceed or exceed the specified voltage by more than 10%. Also, check the water flow path for normal operation.

2. If you have an electrical insulation meter, perform monthly measurements. If the insulation resistance is below 1 MΩ, the motor should be replaced.

3. Every 6 months, change the lubricating oil and replace the mechanical seal, as the rubber is constantly exposed to water pressure.

4. Every 2-5 years, the pump should be lifted and inspected regularly for dirt or debris to prolong its life.

"When performing maintenance on submersible pumps, always disconnect the power supply.This could be dangerous to the operator."For more information

Tel. 02-292-1067-70

Youtube : Leopump ประเทศไทย

Line Official : @775ruust

Facebook : LEOpumpThailand

TikTok : Leopumpthailand

ความคิดเห็น